Download full AFSS brochure

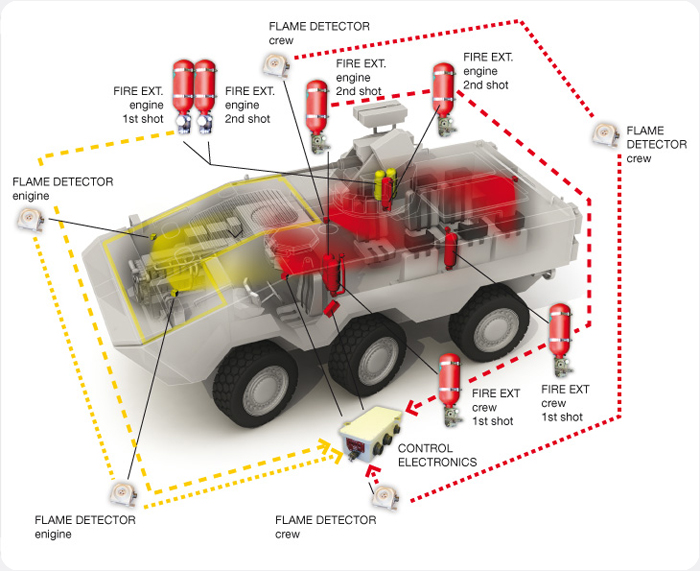

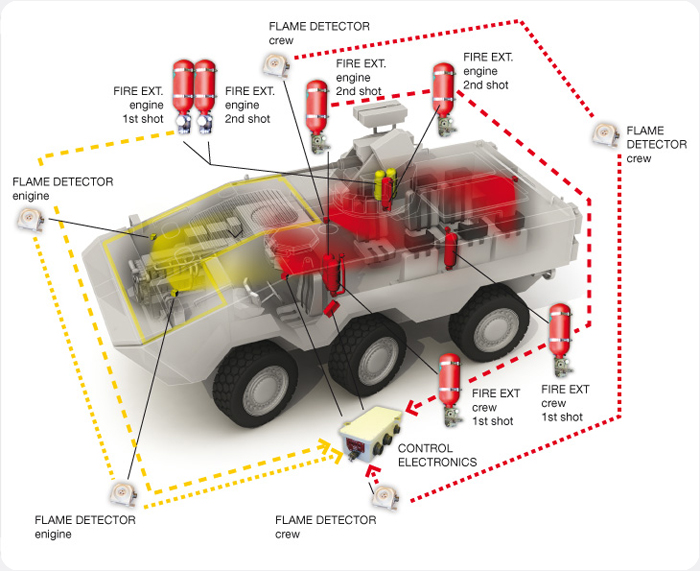

A medium or heavy military vehicle may have two to four compartments to be protected. Crew, Engine, APU, Payload or ammo locker can be protected by the same control electronics plus optical sensors and explosion suppressors. The vehicle driver can monitor the status of the AFSS system through a control panel with leds and switches. In the example shown the vehicle engine is equipped with a dual shot extinguisher system and two sensors: in case a fire is detected by any of the two sensors, one extinguisher will be automatically released while the second extinguisher will be ready as a backup that the driver can manually activate from the control panel in case of re-ignition. The crew AFSS is configured with 3 optical sensors and a dual shot system with two extinguishers per shot: in case a fire is detected by any of the 3 sensors, two extinguishers located in different points of the vehicle will be discharged at the same time. After the first discharge, the vehicle is still protected against a second fire or explosion: if this occurs, the control electronics, based on a fire alarm coming form any of the sensor, will trigger the second batch of two extinguishers. The number of extinguishers depends on the volume of the compartment and its clutter: to achieve a good suppression quick distribution from different points of the compartment is essential to rapidly attack the fireball and saturate the volume.

Technical data

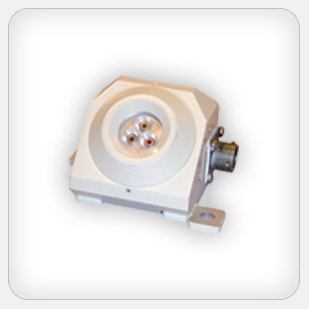

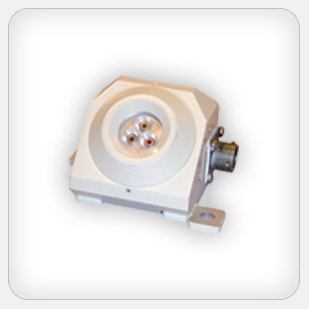

| Infrared flame detector |

|

|

- Infrared tri-band flame detector for hydrocarbon flames

- Explosion response time < 2 milliseconds (Navy certified)

- built-in-self test

- connection cable continous monitoring

- 90° cone field of view

- designed with 45° oriented optics for easy installation

- IP67 degree of protection

- MIL- Standard qualified to shock, vibration, EMI

- operating temperature range from -40°C to + 120 °C

- full metal housing, weight 0,33 Kg.

|

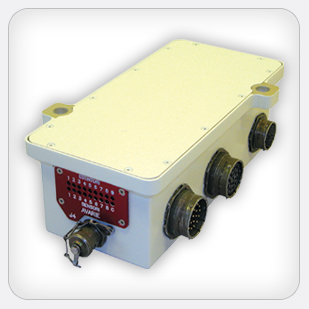

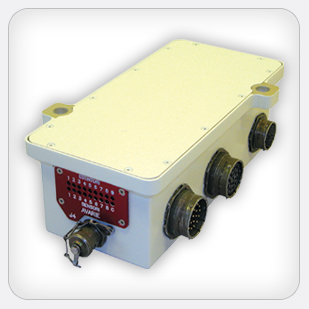

| Control electronics |

|

|

- microprocessor based digital electronics

- can manage up to 4 independent protection zones

- can manage up to 8 flame detectors

- can manage up to 8 extinguishers

- advanced diagnostic with lateral led display

- compact size

- Field and /factory configurable with RS485 connector

- RS485, CANBUS digital interface with vehicle

- digital interface for external I/O

- internal memory log file

- IP67 degree of protection

- MIL- Standard qualified to shock, vibration, EMI

- operating temperature range from -40°C to + 70 °C

- full metal housing: weight 2 Kg.

|

| High rate extinguisher discharge valve |

|

|

- SOLENOID-non pyrotechnic VALVE

- Service pressure 70 bars at 20°C or 105 bars at 70°C.

- DN 32 mm

- Opening time < 10 milliseconds (Navy certified)

- discharge time in less than 100 milliseconds (with standard bottle)

- external gauge, overpressure relief valve

- internal pressure-switch for pressure / leakage monitoring

- both coil and pressure continuous monitoring

- IP67 degree of protection

- temperature range from -40°C to + 70 °C

- ASTM AISI 316 main body, weight 2 Kg.

- Transportable Pressure Equipment Directive 2010/35/EU approved

- Available with and without mechanical override

- low life-cycle cost due to easy RESET after activation:

- no replacement parts needed

|